Standardized & Automated CMYK Production Line

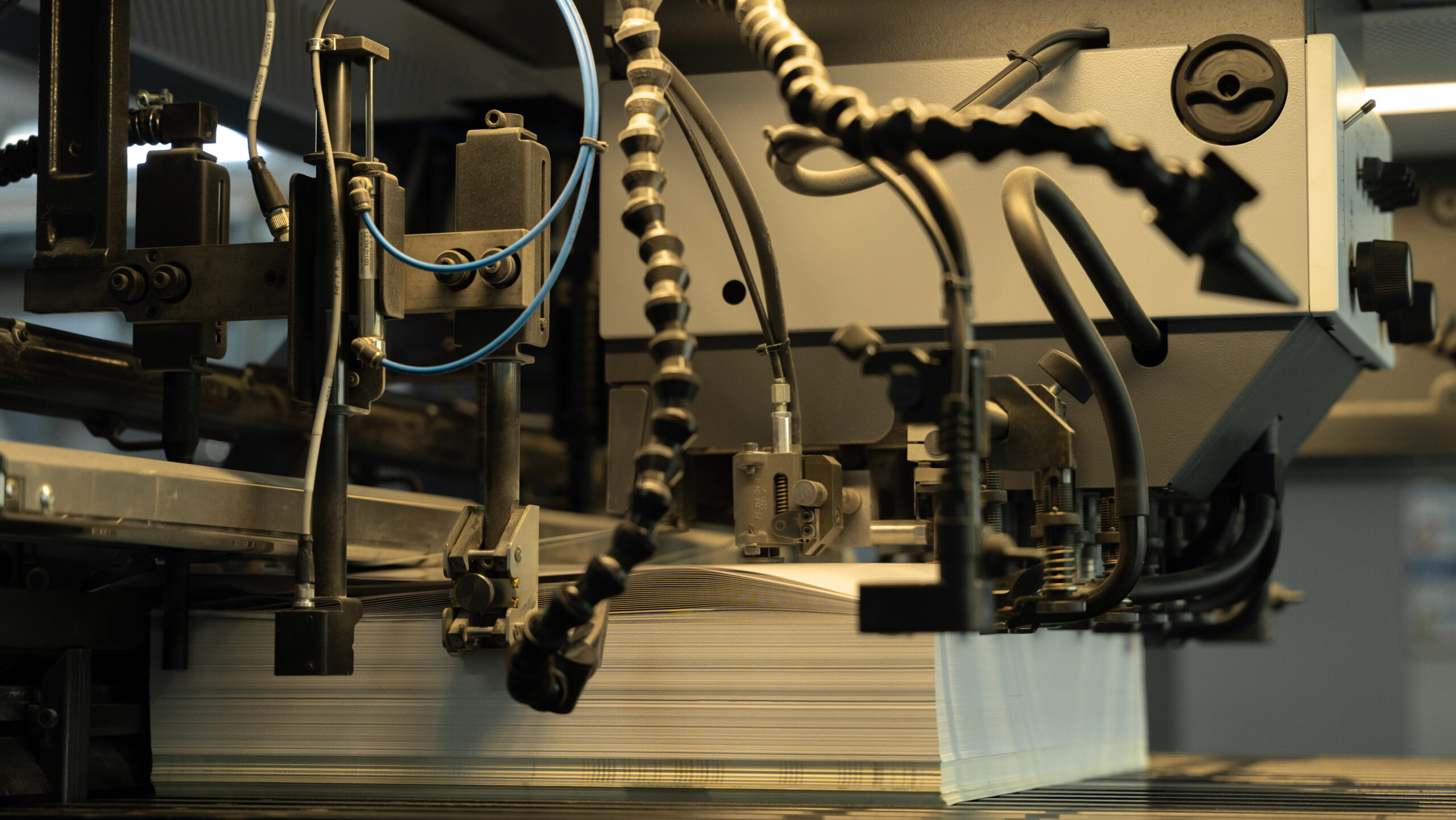

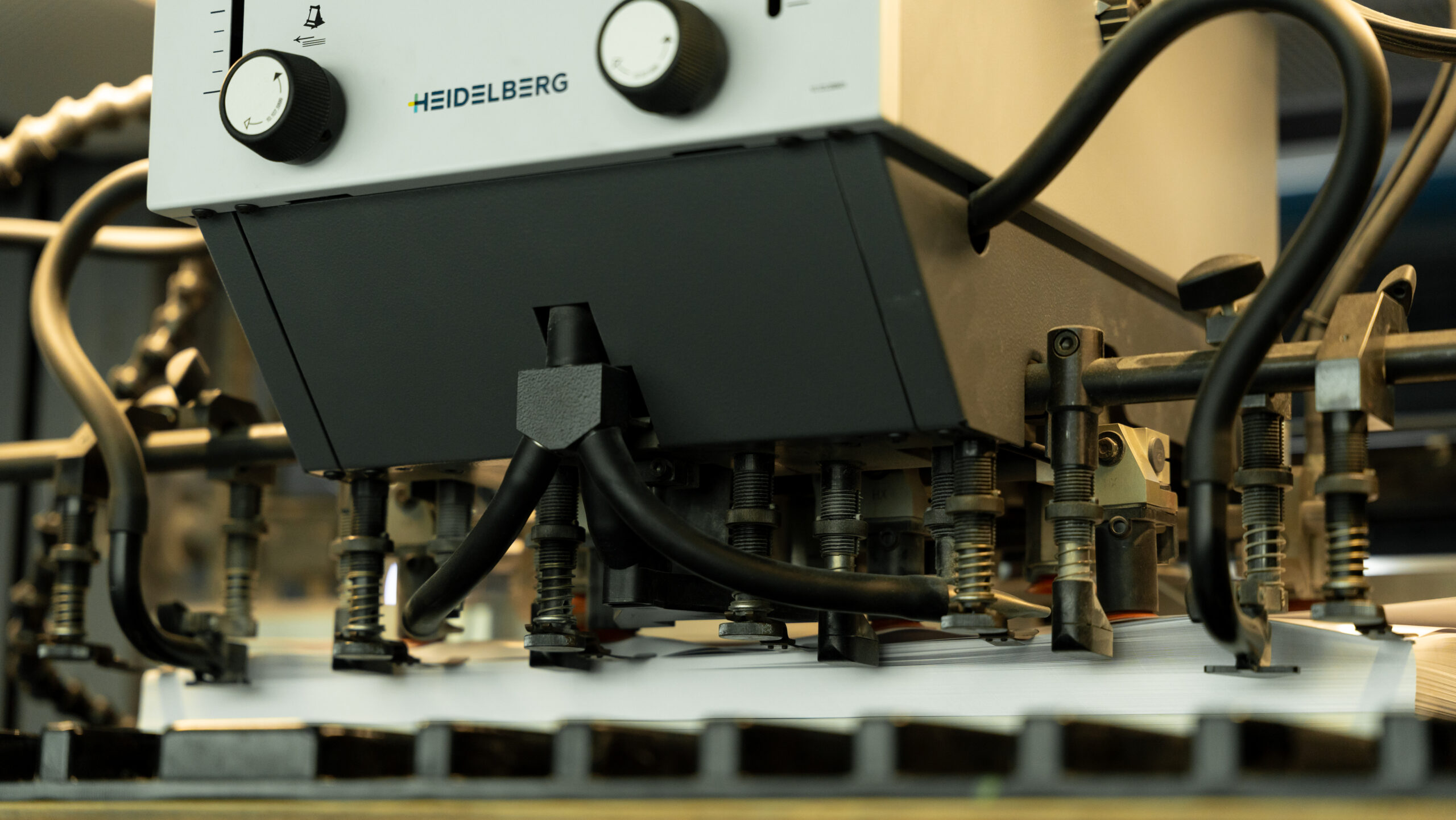

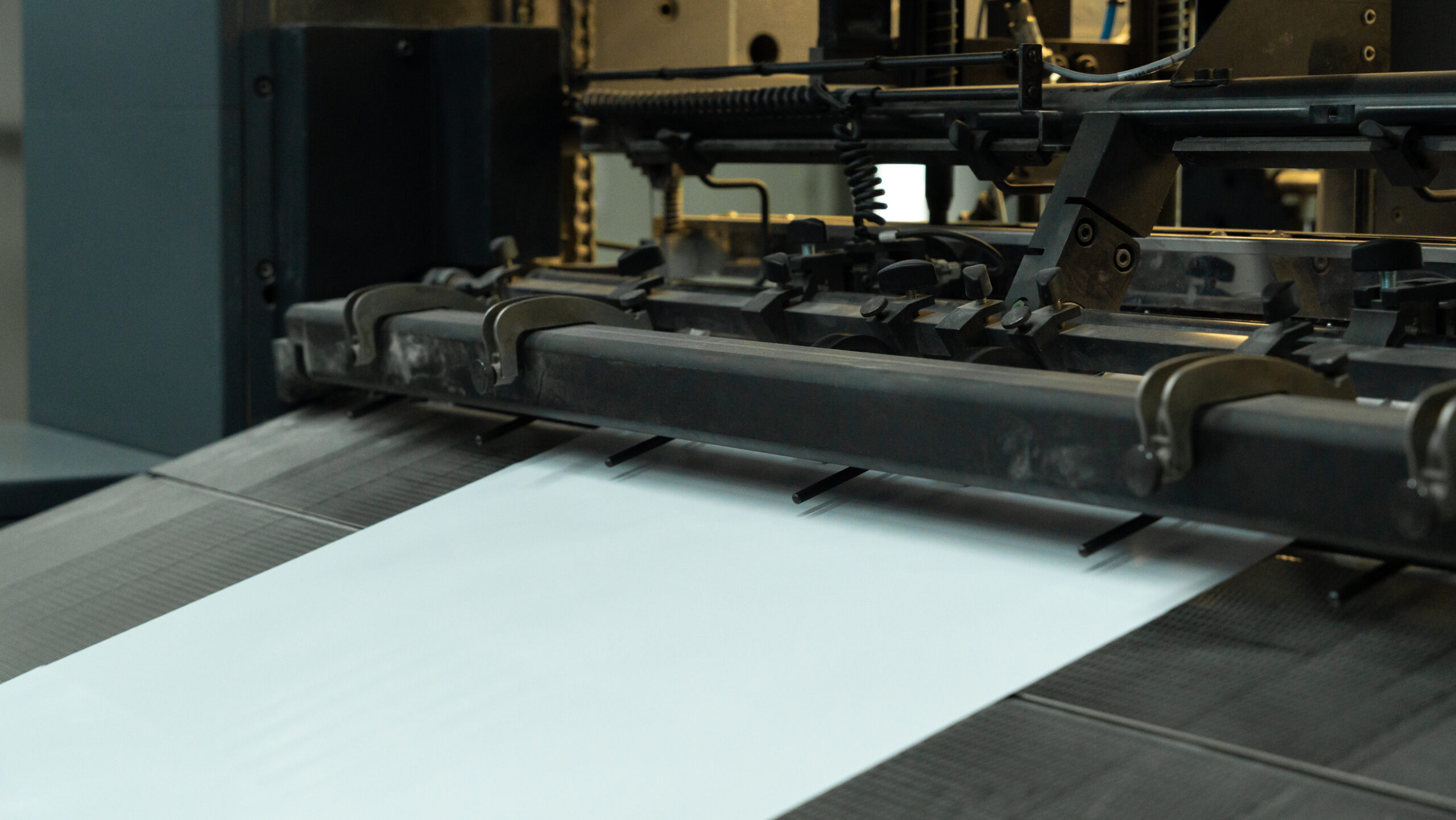

Take a glance at our printing production line below

Intro

Our printing operations are powered by a highly standardized and fully automated CMYK production line. Designed for precision, consistency, and high-volume throughput, our system ensures exceptionally accurate color reproduction across every print run—guaranteed to meet your quality standards every time.

KEY Highlights

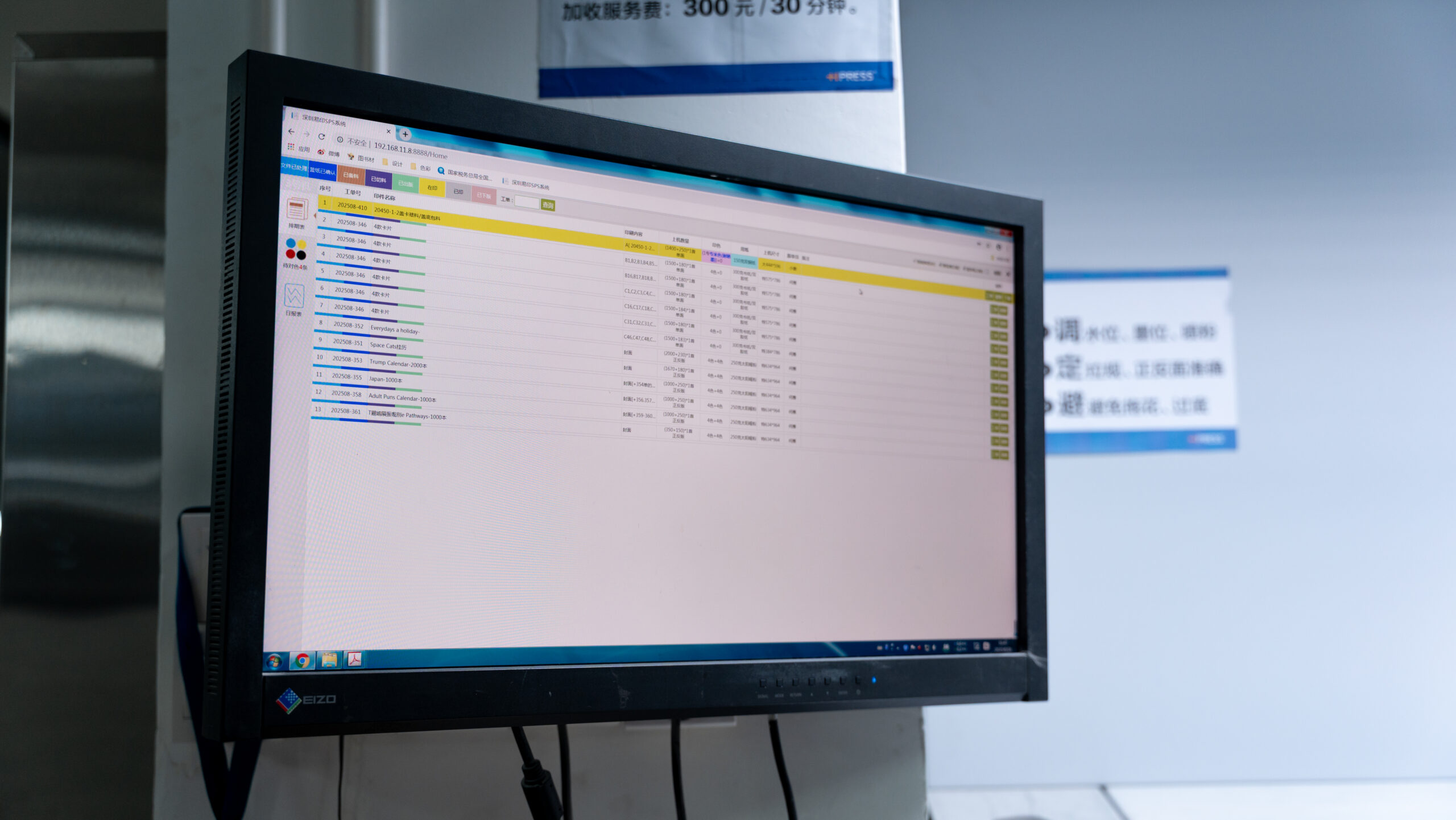

Fully Automated Workflow

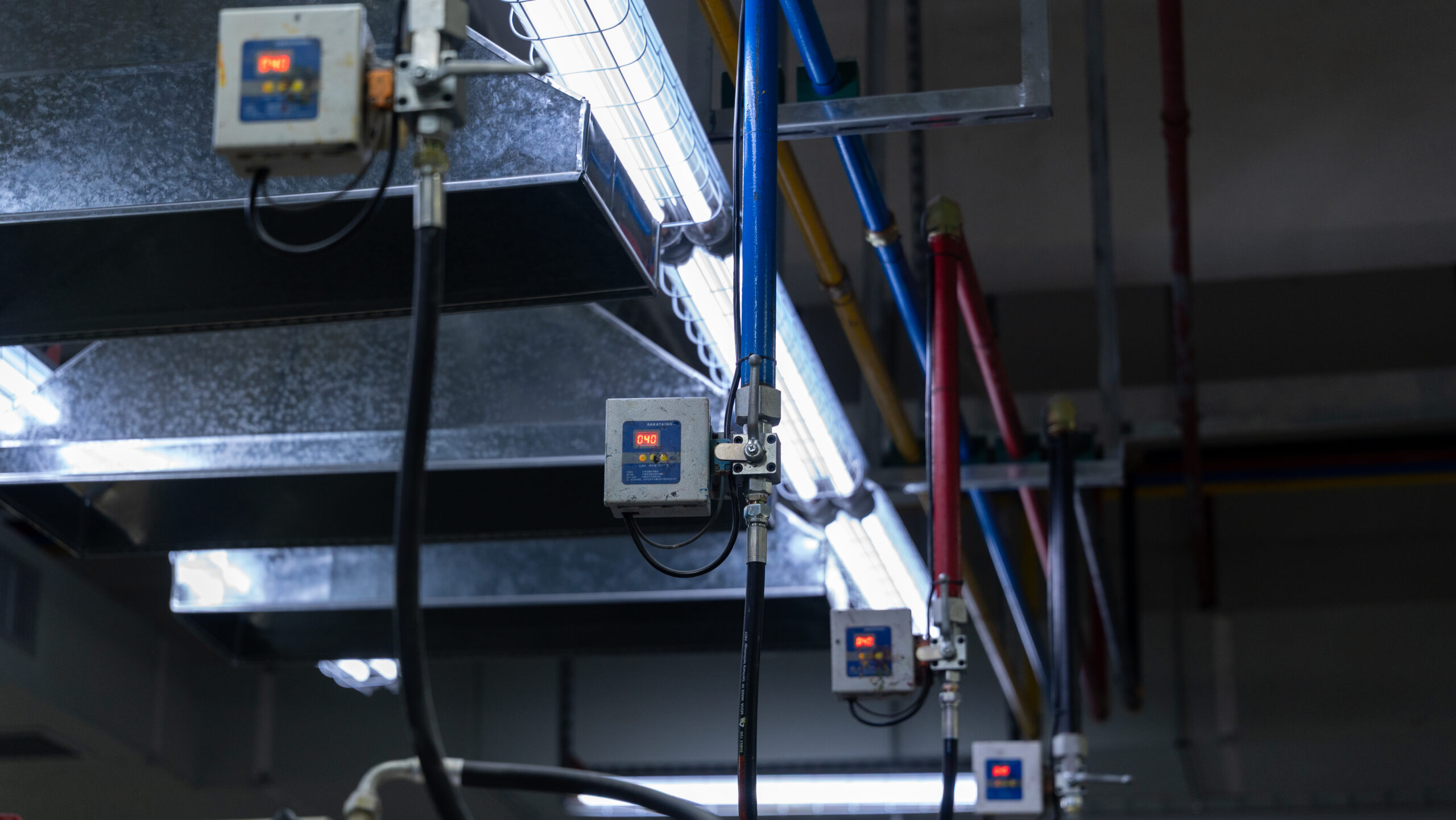

From file preflight and color conversion to printing and post-press processing, our pipeline is engineered for minimal manual intervention—significantly reducing turnaround times and the risk of human error.

Standardized CMYK Color Accuracy

We adhere to rigorous color calibration and inline quality control protocols, ensuring each print matches your brand colors with pinpoint accuracy.

High-Speed & Scalable Production

Leveraging industrial-strength CMYK presses and web-fed continuous systems, our line delivers fast, reliable output—ideal for both large-scale runs and customized production orders.

Seamless Quality Management

With integrated automated color management systems, including inline spectrophotometry and closed‑loop feedback, we maintain color consistency from the first sheet to the last.

Supporting Benefits

Efficiency & Speed

Reliable, high-capacity output accelerates your time-to-market.

Consistent Quality

Uniform color calibration prevents variations—even across repeat orders.

Minimal Waste

Automated color control reduces wasted ink, materials, and reprints—saving costs and protecting the environment.

Flexible Job Handling

Capable of variable data printing, short runs, and last-minute changes—all with full automation.

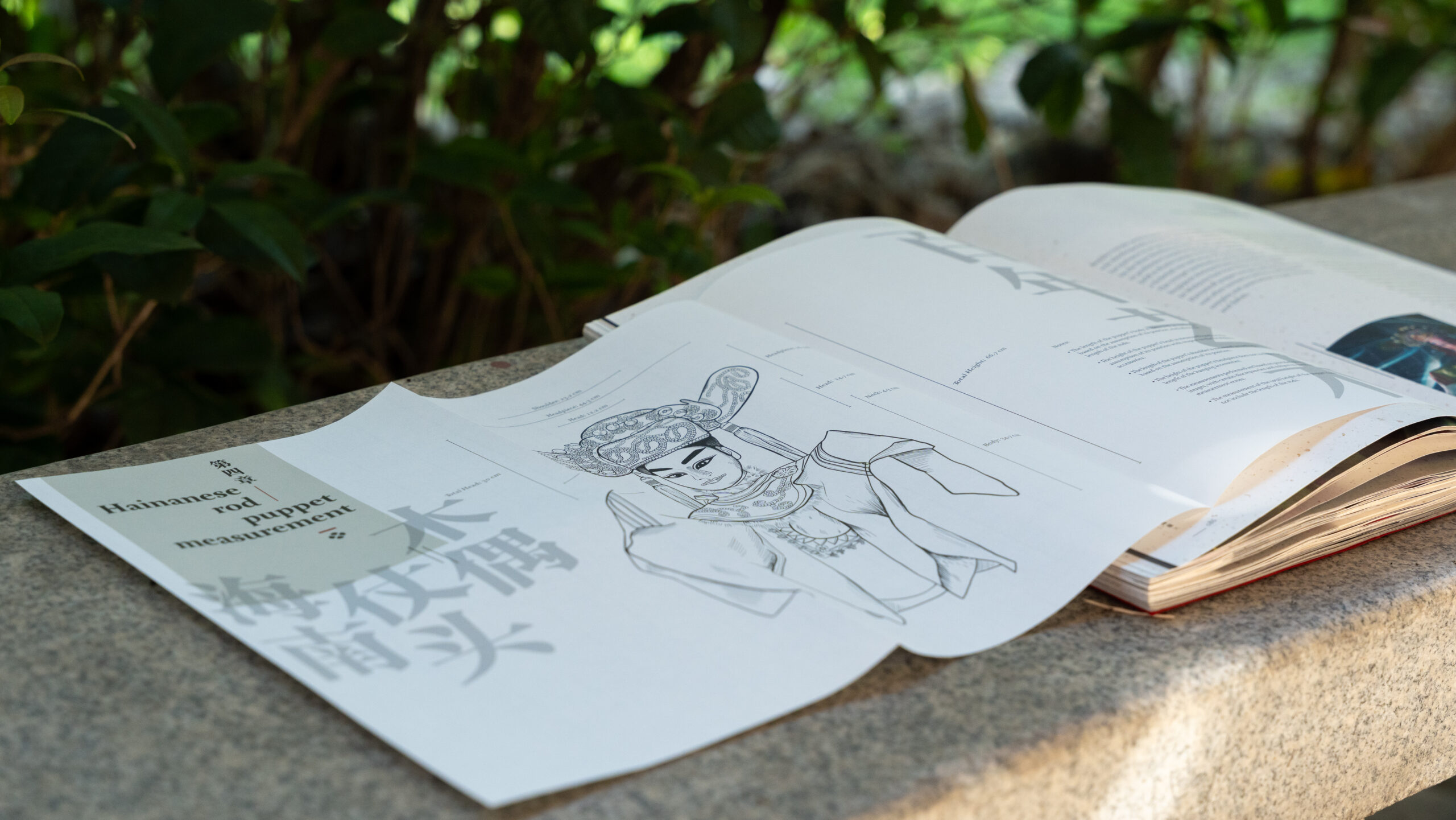

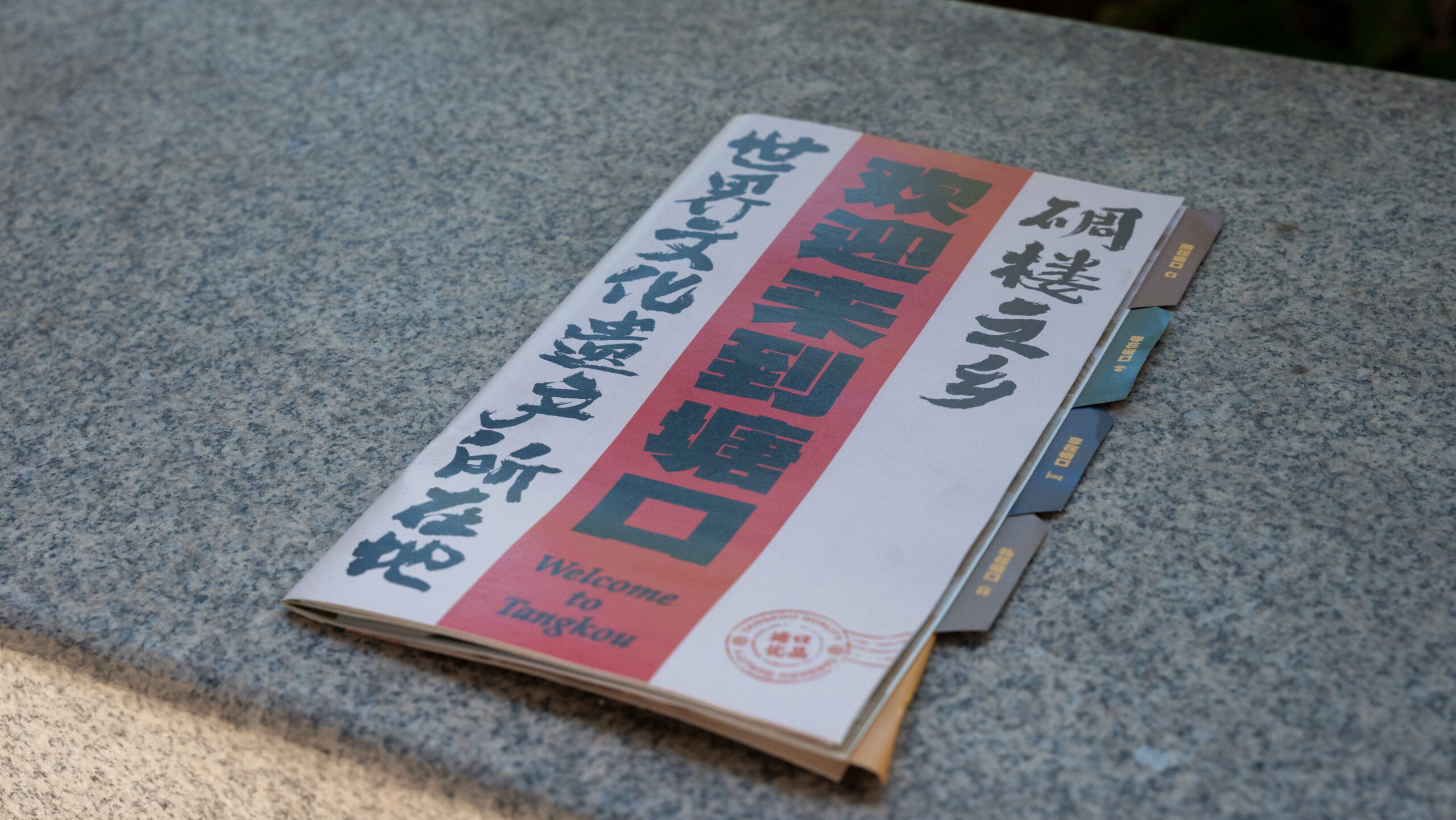

Product Capabilities & Examples

High-Speed Web Presses

Our continuous-feed web presses harness water-based CMYK inks to deliver thousands of full-color pages per minute—perfect for catalogs, magazines, direct mail, and packaging.

Sheetfed Digital Presses with Inline Color Control

Precision-engineered digital presses equipped with inline spectrophotometers ensure spot-on color accuracy and flawless quality control across every sheet.

Variable Data & Short-Run Digital Solutions

Adapt quickly to market demands by printing personalized brochures, labels, or marketing collateral at scale, while maintaining consistent CMYK output.

Location

16 Hutian Road, Pinghu Street,

Shenzhen, Guangdong Province,

China

Pages

Contact us

Tel: (+86)13823284148

E-mail: bytengbob@foxmail.com

Postal Code: 518111

Achieve the Designer’s Dream.